The fully continuous pyrolysis plant is more prominent in the market than batch pyrolysis plant and semi-continuous pyrolysis plant due to the high level of computerization and bigger limit. Talking about the high level of mechanization, a fully continuous pyrolysis plant is outfitted with programmed bolstering and releasing framework, which can understand sustaining materials on one side and release slag from the opposite side continuously. Know what a fully continuous pyrolysis plant can do for you.

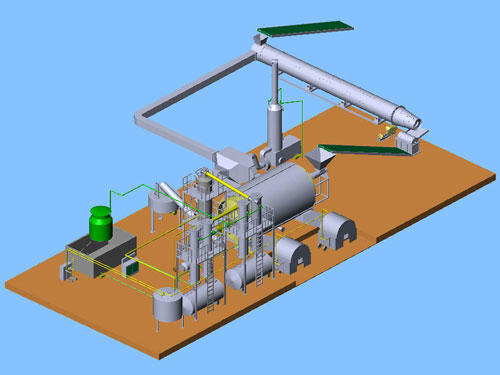

continuous pyrolysis plant

A fully continuous pyrolysis plant can deal with waste tires, waste plastics, waste rubber items, medical waste. So to guarantee the working effectiveness, the raw material should achieve the standard. For waste plastic, the water substance ought to below, and we can prepare the dryer for you on the off chance that you require dry the waste plastic. For the waste tire, it ought to be processed into 50 mm little pieces by the tire crusher. On the off chance that you need to utilize it to discard the medical waste, you should first spotless and purify the medical waste.

Workflow of a Fully Continuous Pyrolysis Plant

1. The processed raw material is put into the pyrolysis reactor consequently. At the point when the inward temperature of the pyrolysis reactor achieves a related degree, the oil gas will be produced. Know what a pyrolysis equipment can do for you.

2. At that point, the oil gas goes into the complex right off the bat. In the complex, the substantial oil gas will be melted into overwhelming oil and drop in the substantial oil tank. The light oil gas ascends to the condenser, and after that be melted into the oil. In the hydro seal, the flammable gas will be desulfurated and cleaned at that point reused to warm the pyrolysis reactor.

4. With respect to the carbon dark, it will be released by the auto screw discharger.

Advantages of a Fully Continuous Pyrolysis Plant

To begin with, it embraces tube sort condenser, which has bigger cooling territory and better cooling impact, so the tube condenser can expand the cooling proficiency. Know the next thing what a fully continuous pyrolysis plant can do for you. Get pyrolysis plant cost here.

Second, the continuous pyrolysis reactor is steady and not turning, which makes the temperature rise and pyrolysis respond rapidly. This unique outline makes the entire pyrolysis handle a great deal more effective and the vitality sparing. Along these lines, the interest in the vitality is lower.

The third to know what a fully continuous pyrolysis plant can do for you is the security configuration can ensure the specialists as well as ensure the earth. The packaging can guarantee that the high temperature won’t make hurt the specialists. What’s more, the disturbing framework can guarantee that the specialists have a protected working condition.

Fourth, it can keep running for 24 hours every day without a stop and there is no compelling reason to chill off the reactor before the second batch.

The last yet not the minimum thing to know what a fully continuous pyrolysis plant can do for you is the advantages the plant can realize is a key. You can offer the pyrolysis fuel oil, carbon dark straightforwardly, and you can likewise enhance the nature of the carbon dark and pyrolysis oil to give them a chance to have a higher market esteem.

Use of final results from waste plastic pyrolysis

1. Plastic pyrolysis oil can be specifically utilized as the fuel oil for ship, and it can be additionally grouped and processed, at that point development of oil items, for example, oil, diesel with high advantages.

2. The pyrolysis slag can be utilized as elements for building materials.

For the pyrolysis oil refining, we can give you the waste oil refining plant. With respect to the carbon dark handling, the carbon dark preparing plant available to be purchased is accessible. The flammable gas can warm the pyrolysis reactor after the reusing procedure, which can likewise lessen your interest in vitality. Learn more what a fully continuous waste tyre pyrolysis plant can do for you.

The Exit Strategies

The Exit Strategies