Are you in search for a quality electric winch? If so, you must be aware of the most important factors to consider in order to select the right winch for the job. It’s important to note that there are different kinds of electric winches and motors to choose from. You might be overwhelmed by the number of choices on the market, but by knowing exactly what you need you should be able to find a winch with the proper specifications. This guide aims to help you choose the best electric winch for your specific application.

What Is An Electric Winch?

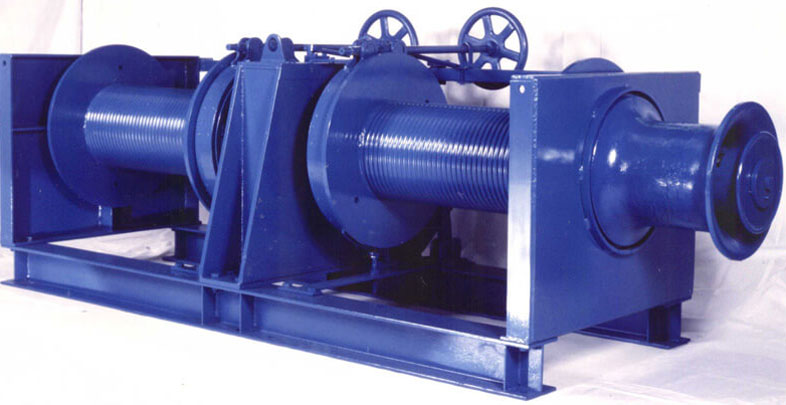

When talking about electric winches, many tend to think that these pieces of equipment are exclusively used in industrial environments. However, it pays to learn that there are winches that can be mounted on vehicles and boats. These tools serve as a hoist when lifting heavy objects. For example, an electric winch can be used as a vehicle accessory, particularly on off-road vehicles. They are usually used to move very heavy objects or in case the vehicle is in a bind, a winch can be used to pull it out.

It’s also essential to understand that electric winches are often powered by a 240-volt AC circuit or a standard 12-volt battery car. Choosing the right power source is vital to ensure that the winch does its function optimally. Winches and motors can be found in home improvement and auto parts stores. In some cases, they can also be purchased from recreational vehicle dealers and department stores. There are also plenty of online marketplaces where you can find vendors.

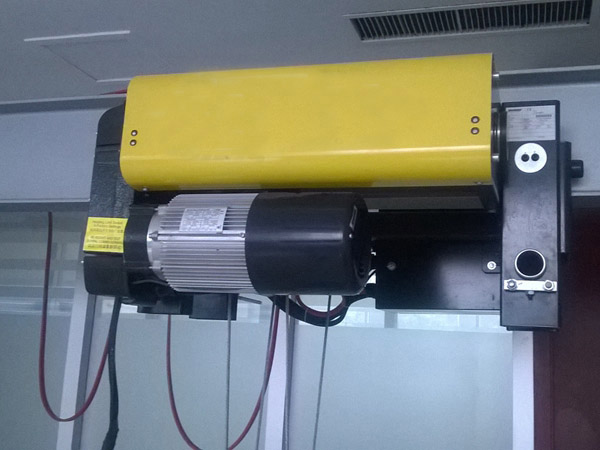

Choosing The Right Motor

When doing your shopping, you抣l stumble upon a number of different winch motors. There are basically two types to choose from: permanent magnet (PM) and series wound (SW). For heavy duty applications, the recommended motor is SW. This motor also works in all types of weather. On the other hand, PM is more suited for light duty applications. If you抮e living in a place with cold weather conditions, however, PM motors may not be the best choice because they tend to perform poorly.

How To Find The Right Electric Winch

The most convenient way to look for the perfect electric winch is to conduct a search online. You can go to an online marketplace or a search engine and enter the search terms electric winch.?This should return a large selection of winches with different specifications. If you know exactly the kind of winch you need, then you can add keywords such as 20,000 lb electric winch to narrow down your choices. Be sure to contact the vendor before making a purchase. It is better to be crystal clear about the specifications of the winch to ensure that you抮e buying the right one for your needs.

Electric winches are extremely useful tools for businesses that require the lifting and transportation of large and heavy objects. By following the tips mentioned in this guide, you should be well on your way to finding the right electric required for the job.