Plastic waste pyrolysis technology could well be the answer to the problem of waste plastics in the US. According to a recent study on emergying technologies, pyrolysis plant has anumber of environmental benefits, and offers massive cost savings over disposing of the waste into landfill.

The study, which was commissioned by the American Chemistry Council’s Plastic’s Division, was conducted by an independent and not for profit institute called RTI International. The scientists looked at two main kinds of conversion technology – namely pyrolysis and gasification. They found that both of those technologies are useful for processing a lot of different kinds of waste. Gasification is more versatile, and can handle a wider range of wastes, however waste plastic to oil machine has a lot of value because it can turn plastic into oil or gas, saving as much as 3.6 million BTU a ton, as well as reducing waste by up to 0.25 tons of carbon equivalent for each ton of waste, when compared to disposing of waste into landfill. If you wanna know tyre recycling plant cost, visit Beston.

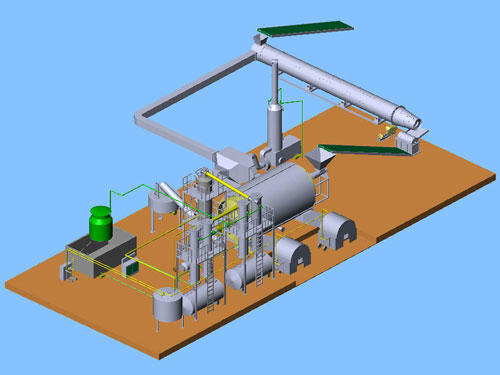

The researchers looked at 41 advanced conversion facilities which are working in the USA, and that accept non-recycled plastic for work.

They reported that the benefits of the technologies in use in these plants are things that are going to become incredibly important to North Americans over the next several years. Conversion technologies are expensive to set up, but they have a lot of value, and they are consistent, energy efficient, and actually less expensive, in many ways, than landfill. They are perhaps the easiest way of developing an alternative energy source, and they empower companies to meet their waste diversion targets.

It is interesting to note that they produce lower cost fuel output, and that they can be used to process waste at a cost of just $50 per ton. The cost for disposing of waste into landfill can be as low as $30 a ton in some areas, but in other parts of the country it can reach $75 a ton. This makes pyrolysis eminently appealing.